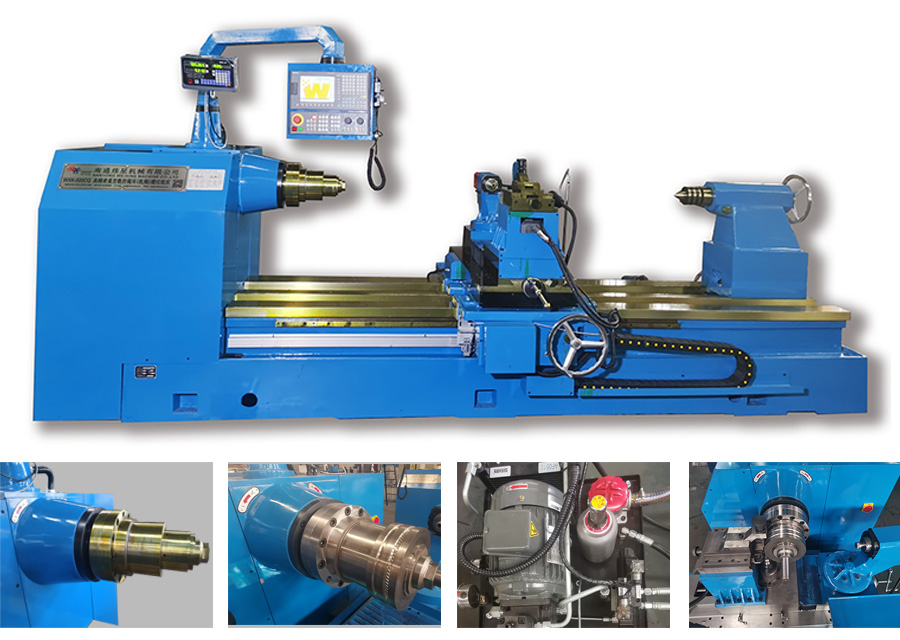

Machine Features

The high-precision heavy-duty CNC roll thread milling machine has the advantages of high degree of automation, high machining accuracy, high cutting efficiency, safe and reliable operation, etc. The machine tool meets the requirements of slot milling, slot-hopping, and lettering in one clamping, without the need for secondary clamping of the roll.

The machine bed is a heavy-duty roll machining machine with three parallel guide rails. The width of the bed must reach 910mm, and the width of the saddle must reach 810mm, so as to ensure sufficient rigidity and anti-vibration performance of the machine tool as a whole, so as to be suitable for milling high-hardness tungsten carbide roll rings and high-speed steel. roll. At the same time, it can meet the exchange of hydraulic tensioning shaft and chuck.

The longitudinal movement of the large carriage of the machine tool is equipped with a locking mechanism to ensure that there is no waste groove caused by center deviation when machining high-hardness rolls or performing large cutting operations.

The flying cutter milling body and the swing milling body are installed relative to each other, and the two do not interfere, and the functions of milling grooves and lettering can be converted without re-disassembly and assembly of parts, and there is no need for electrical switching.

The machine bed is treated with aging or fully annealed, and the guide rail is treated with intermediate frequency quenching to reach HRC48°-52°, which improves the wear resistance of the surface; the lateral feed guide uses rolling linear guides to reduce frictional damping and improve moving accuracy. Under normal use, the linear guide will not be worn for 10 years.

The engraving and milling shaft adopts an electric spindle (customized by our factory: rigid enough, uniform force, good heat dissipation, high configuration) directly installed without excessive connection, and can be arbitrarily engraved on rollers of different materials.

The machine tool is equipped with a manual tool setting mechanism, and is equipped with a magnetic grid digital display in the longitudinal movement of the large carriage to ensure the accurate displacement of the manual slot change and eliminate the phenomenon of edge collision caused by human visual inspection.

The control adopts SINUMERIK_808D_ADVANCED system, LCD display, bus-type drive, which can realize any three-axis linkage. All Siemens servo system, the 4 control axes of the machine tool are independent motors and drives. The system has good dynamic quality, and the selected servo system has high execution precision, good reliability, strong anti-interference ability and fast response speed. Each motion axis can be controlled by electronic handwheel.

Weixing independently develops special processing software and parameter interface programming. Operators do not need CNC foundation and can easily master operation skills. Ensure that the processed crescent socket meets the standard of GB1499.2-2018.

This machine tool ensures that the processed crescent groove meets the standard of GB1499.2-2018.

The equipment has good operability, maintainability and safety performance, and does not pollute the environment and endanger human health.

The main shaft structure of this machine tool adopts hydraulic tensioning shaft mechanism and is equipped with high-precision Taiwan hydraulic station. The hydraulic tensioning shaft of the main shaft can control the tensioning state through the system, which greatly improves the efficiency of the cemented carbide roller ring in the clamping and calibration. During the clamping process, the automatic calibration accuracy is automatically locked, and the manual calibration accuracy is not required. At the same time, it also meets the exchange of hydraulic tensioning shaft and chuck.

Main specifications and technical parameters

The maximum diameter of the processing roll is 500mm

Minimum diameter 50mm

The maximum length of the processing roll is 2500mm

The maximum length of the processing roll surface is 1800mm

Machining crescent socket specifications Φ6~Φ50

Machining crescent alveolar β angle arbitrary

Processing crescent grooves and job-hopping

Lateral movement speed (X axis) 0~6000mm/min

Workpiece rotation speed (Y axis) 0~30rpm

Swing head rotation speed (Z axis) 0~50rpm

Flying cutter milling speed (A axis) 0~600rpm

Engraving electric spindle model rated speed D85 24000rpm 2.2Kw

Cooling pump motor AB25-90W

Control system Siemens 808D

Servo motor rated power X axis 1.75kw

Y-axis 2.5kw

Z-axis 1.75kw

A-axis 3.5kw

Hydraulic station 2.2KW

Minimum programming amount 0.001

The effective measuring length of longitudinal magnetic scale is 2000mm

Grating accuracy 0.005mm

Chuck form Four-jaw chuck and hydraulic tensioning shaft are interchangeable

Chuck diameter 400mm

Hydraulic tensioning shaft size Customized according to customers